Types of Heat Exchangers for Commercial Applications: Pros and Cons

Spend any time in a plant room, and you’ll soon notice one component that quietly keeps everything running: the heat exchanger. It might be a large shell-and-tube unit mounted beside the boilers, or a compact plate unit tucked behind the pressurisation system, but it’s always there, doing the hard work of transferring heat safely and efficiently between circuits.

For anyone maintaining or designing commercial heating systems, understanding the different types of heat exchanger is essential. Each type has its strengths, weaknesses, and ideal applications. Get it right, and you’ll have reliable, efficient operation for years. Get it wrong, and you’ll end up with poor performance, high energy costs, and frustrated clients.

This guide breaks down the main designs used in commercial environments, explaining how they work, where they fit best, and what trade-offs come with each. It’s a practical heat exchanger comparison based on real engineering experience rather than marketing claims.

Why Heat Exchangers Matter in Commercial Systems

A heat exchanger does exactly what its name implies: it exchanges heat between two fluids without mixing them. In a typical heating system, that means transferring energy from a primary circuit, the boiler or heat pump sid,e to a secondary circuit, the heating or hot water side.

By keeping the fluids separate, the exchanger prevents contamination and allows each side to operate under different conditions. It also provides protection against corrosion and system fouling, especially where old pipework meets new plant.

In commercial projects, this separation is critical. It enables engineers to:

- Maintain system hygiene by isolating treated and untreated water.

- Protect sensitive components such as condensing boilers.

- Balance multiple temperature zones efficiently.

- Carry out maintenance on one side of the system without shutting down the whole building.

Without the right exchanger in place, even the most advanced boilers or pumps won’t deliver the efficiency promised on paper.

The Main Types of Heat Exchangers

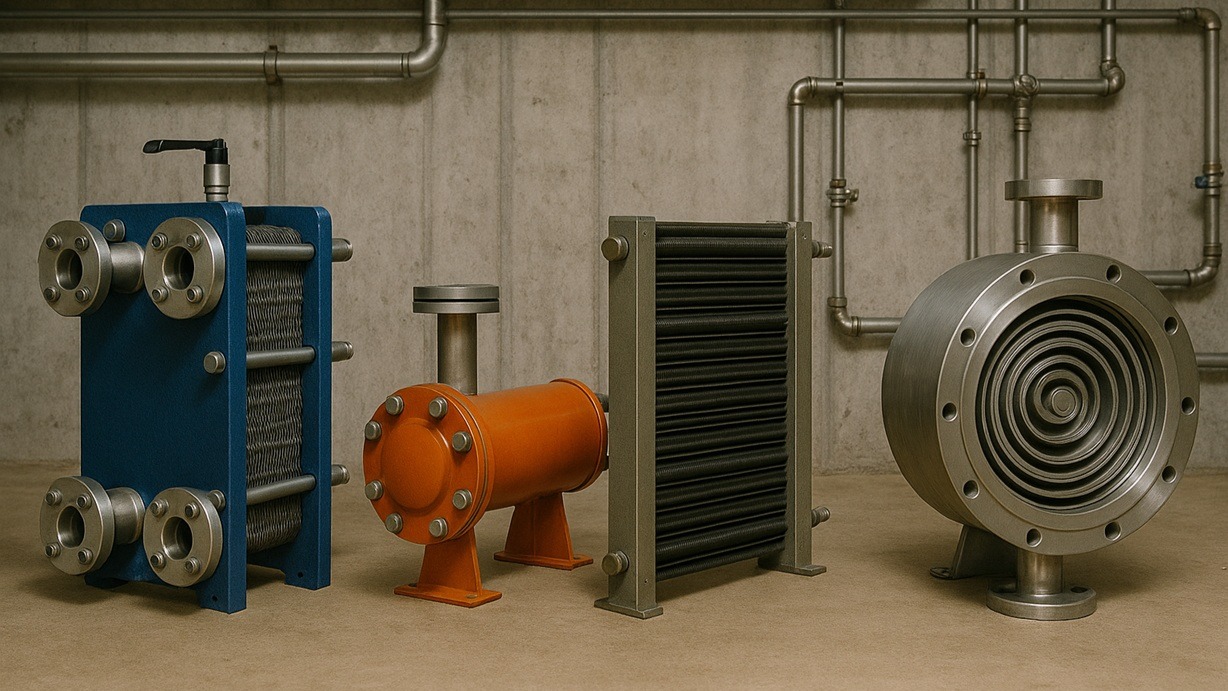

In commercial heating and cooling, there are four designs that cover most applications:

- Plate heat exchangers.

- Brazed plate heat exchangers.

- Shell and tube heat exchangers.

- Air-to-water or finned coil heat exchangers.

Each design works differently and suits specific operating conditions. Below is an engineer’s view of how they perform in the field.

Plate Heat Exchangers

How They Work

A plate heat exchanger consists of multiple thin, corrugated metal plates stacked together within a frame. Hot and cold fluids flow through alternate channels, and the thin metal plates conduct heat between them. The corrugation increases surface area and turbulence, improving heat transfer.

Where They’re Used

These exchangers are common in commercial boiler systems, district heating, and domestic hot water generation. They are also used to connect renewable systems such as ground or air source heat pumps to legacy pipework.

Advantages

- Excellent thermal efficiency in a compact size.

- Straightforward to clean and service.

- Easy to replace or resize during system upgrades.

- Cost-effective for medium to large systems.

Drawbacks

- Require good water quality to prevent fouling.

- Gaskets can deteriorate over time and may leak if not maintained.

- Not ideal for systems with heavily contaminated or open water circuits.

Practical Note

Always fit isolation valves and drain points on both sides. It makes maintenance and flushing easier and avoids unnecessary downtime. For systems using Pressurisation Units or Expansion Vessels, plate exchangers integrate seamlessly and help maintain stable operating conditions.

Brazed Plate Heat Exchangers

How They Work

A brazed plate heat exchanger works on the same principle as a gasketed plate type, but the plates are permanently bonded together with a thin layer of copper or nickel during manufacturing. This creates a sealed, compact, and highly efficient unit with no gaskets to maintain.

Where They’re Used

Brazed plates are common in heat pump systems, chillers, and other closed circuits where the water is clean and chemically stable. They are especially popular where plant room space is limited.

Advantages

- Very compact and lightweight.

- No gasket maintenance required.

- Handles high pressures and temperatures.

- Typically cheaper than gasketed plate units.

Drawbacks

- Cannot be opened for cleaning; if fouled, replacement is the only option.

- Sensitive to poor water treatment.

- Copper-brazed types can corrode in open or aggressive systems.

Field Insight

On-site experience shows that these exchangers perform exceptionally well when water quality is maintained. However, even small particles can cause blockage. Always install dirt filters and air separators upstream. High-quality products from Flamco work well for this purpose.

Shell and Tube Heat Exchangers

How They Work

A shell and tube exchanger uses a bundle of tubes enclosed within a cylindrical shell. One fluid flows through the tubes, while the other passes around them within the shell. Heat transfers through the tube walls. This traditional design has been around for decades and remains a reliable workhorse for large-scale applications.

Where They’re Used

They’re common in hospitals, factories, and central energy plants where high pressures, dirty fluids, or continuous operation are involved.

Advantages

- Very robust and durable.

- Can handle significant pressure and temperature differences.

- Tolerates fouling better than plate designs.

- Easier to repair individual tubes.

Drawbacks

- Large and heavy, requires substantial floor space.

- Lower efficiency compared with modern plate units.

- More labour-intensive to clean and maintain.

- Higher material and installation costs.

Engineer’s Perspective

Think of this design as the “industrial boiler” of heat exchangers. It might not have the sleek efficiency of newer types, but it keeps running under tough conditions for years. If your system deals with dirty or variable fluids, this is the safe choice.

Air-to-Water Finned Coil Heat Exchangers

How They Work

These exchangers use copper or aluminium tubes fitted with fins. Hot or cold water flows through the tubes, and a fan blows air across the fins to transfer heat. The concept is simple but effective for heating or cooling large air volumes.

Where They’re Used

You’ll find them in air handling units, fan coil systems, and warm-air heating. They’re also used in industrial processes that need air tempering or ventilation.

Advantages

- Ideal for space heating and ventilation.

- Straightforward to control and integrate with existing BMS systems.

- Light and modular in design.

Drawbacks

- Dust and dirt reduce efficiency quickly if not cleaned.

- Fins can corrode in damp or coastal environments.

- Requires consistent maintenance and good filtration.

On-Site Observation

In real-world installations, corrosion is the most common problem. Using coated or stainless fins from manufacturers like Ebara can significantly extend service life in harsh environments.

Hybrid and Specialised Designs

Beyond the standard four, there are a few specialist designs worth noting for unique applications.

- Spiral heat exchangers are used in wastewater treatment or processes with high-viscosity fluids.

- Double-wall plate exchangers prevent cross-contamination in sensitive systems such as hospitals.

- Micro-plate exchangers feature enhanced geometry for improved heat transfer at low flow temperatures, often paired with renewable systems like ground source heat pumps.

While you won’t see these every day, it’s useful to understand their role when dealing with bespoke or large-scale commercial projects.

Choosing the Right Heat Exchanger for the Job

When deciding between designs, several factors need consideration beyond simple capacity or size.

- Water Quality

Clean, closed systems suit plate or brazed designs. Dirty or open systems benefit from shell-and-tube types that can handle debris. - Temperature Range

For high temperature differentials, plate units offer excellent performance. For consistent high-pressure duties, shell-and-tube remains the safer option. - Space and Access

Tight plant rooms often dictate the use of brazed or gasketed plate exchangers. Always leave access for maintenance. - Maintenance Resources

Sites with regular maintenance can justify gasketed plates that require periodic cleaning. Where access is difficult, sealed brazed plates might be more practical. - Budget and Longevity

Shell-and-tube units are expensive but last for decades. Brazed and plate types offer better efficiency and lower capital cost but shorter lifespans.

This kind of heat exchanger comparison helps balance short-term project budgets with long-term operating goals.

Maintenance Essentials for Each Type

Plate Heat Exchangers:

Inspect annually, check for gasket wear, and clean plates when performance drops. Avoid overtightening clamps, as this can deform the plates.

Brazed Plate Heat Exchangers:

Monitor pressure differential across the unit. If it rises, the internal passages are likely blocked. Regular filtration upstream will extend service life.

Shell and Tube Heat Exchangers:

Brush-clean the tubes and inspect the shell for corrosion. Pay attention to water chemistry, particularly where steam is involved.

Air-to-Water Heat Exchangers:

Clean fins and filters regularly. Blocked airflow drastically cuts heat transfer. Replace damaged fins to restore airflow efficiency.

No matter which type is installed, always monitor flow temperatures, delta-T, and pressure readings. They are the best indicators of system health.

Case Example: System Upgrade in an Educational Building

An ageing secondary school heating system in Leeds was due for an upgrade. The existing plant included two old shell-and-tube exchangers linking the boilers to the distribution system. Efficiency was poor, and the units were heavily scaled.

The engineering team replaced them with modern plate heat exchangers to provide better heat transfer and easier maintenance access. They also installed Mikrofill pressurisation equipment Mikrofill to keep the system pressure stable and added new Pump Valves for isolation.

Post-commissioning results showed a 22 per cent improvement in thermal efficiency and smoother control of flow temperatures across the building.

Improving Efficiency and Longevity

Even with the right design, performance depends on how the exchanger is maintained. Small changes can make a significant difference.

- Install Proper Filtration

Magnetic and dirt filters are essential for protecting the plate pack. A filter costs little compared with replacing an exchanger. - Treat the Water

Follow BS 7593 for inhibitor and biocide dosing. Poor chemistry ruins efficiency faster than most realise. - Control Pressure Automatically

Use reliable pressurisation units and expansion vessels to prevent air ingress, which causes corrosion. - Optimise Pump Operation

Pair exchangers with variable-speed pumps from Wilo or Grundfos. They maintain correct flow without wasting energy. - Monitor and Record Data

Logging inlet and outlet temperatures helps identify fouling early. A narrowing delta-T is the first sign of trouble.

Routine checks and clean water go a long way to extending life expectancy. Neglect, on the other hand, shortens it dramatically.

Common Issues Encountered on Site

A few recurring problems come up across most commercial projects.

- Reduced Heat Output: Usually caused by fouling or incorrect flow direction. Counterflow arrangements are always more efficient than parallel flow.

- Cross-Contamination: Indicates gasket failure or internal leakage. Isolate and test both sides immediately.

- Corrosion: Occurs when incompatible materials or untreated water are used. Ensure stainless steel grades match system requirements.

- Vibration and Noise: Often a sign of pump overspeed or cavitation. Verify the pump curve and fit suitable controls.

Engineers should also check insulation around exchangers. Exposed metal loses more heat than you might expect.

When Replacement Becomes the Right Option

Replacement usually becomes cost-effective when:

- The unit has lost more than 20 per cent of its original transfer capacity.

- Pressure losses remain high despite cleaning.

- Corrosion or pinhole leaks appear.

- The system has been upgraded, and the old exchanger is undersized.

Modern exchangers from Reflex or NPB can offer major efficiency gains. Newer designs often deliver the same output in a much smaller footprint, which is valuable in older plant rooms.

Developments and Future Trends

Technology in this area continues to move quickly. The latest commercial heat exchangers are being designed with built-in sensors for temperature, pressure, and flow monitoring. This allows predictive maintenance through the Building Management System rather than relying solely on routine inspection.

Manufacturers are also refining plate geometry to work more efficiently at lower operating temperatures, which pairs well with heat pumps and renewable systems. Expect to see more compact, modular exchangers that integrate directly with buffer vessels or thermal stores.

The trend is clear: smarter, smaller, and more efficient.

Key Takeaways for Engineers

When you’re comparing different types of heat exchanger, remember that no single design is perfect for every situation. The best choice depends on your system’s reality, the water quality, maintenance access, duty cycle, and budget.

- Use plate exchangers where you need high efficiency and compactness.

- Choose brazed plates for sealed, clean systems where maintenance access is limited.

- Stick with shell-and-tube where reliability under pressure or contamination is more important than efficiency.

- Select air-to-water units for ventilation or space heating applications.

If you’re unsure which to specify, our team at National Pumps and Boilers can provide tailored advice. They supply Commercial Circulators, pump valves, and pressurisation equipment, ensuring all components are compatible and properly matched.

For direct technical support or to discuss project requirements, get in touch with the National Pumps and Boilers engineers. They’ll help ensure your plant room achieves the best possible performance and efficiency.

-

-